Keeping the perfect balance between functionality and performance is challenging and individual. Our cars are always a bit more focused on the performance part of this equation, but leave the roughness of a race car to the race drivers. Each and every classic Porsche we build is unique, but shares the core components like ECU, additional sensors and performance parts.

Interesting engines:

Porsche 964 – Conversion to 3.8L VarioRam and Ecumaster ECU

Porsche 993 – Conversion to VarioRam and Ecumaster ECU

Porsche 931 Turbo S2 – Conversion to MegaSquirt ECU

Porsche 964 – 3.8L VarioRam and Ecumaster ECU

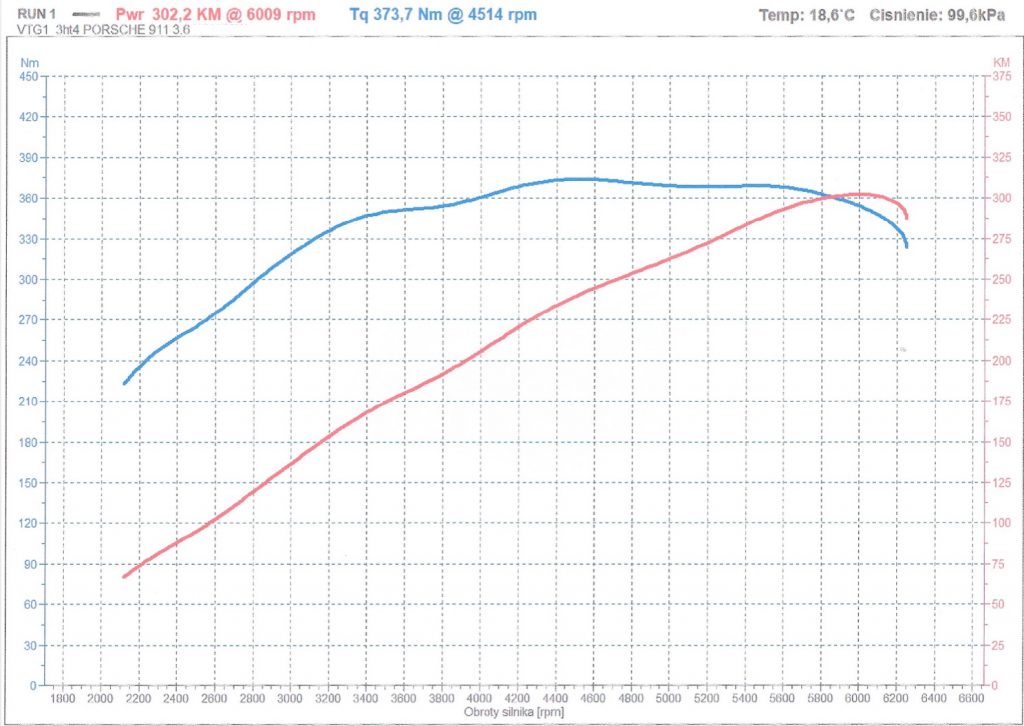

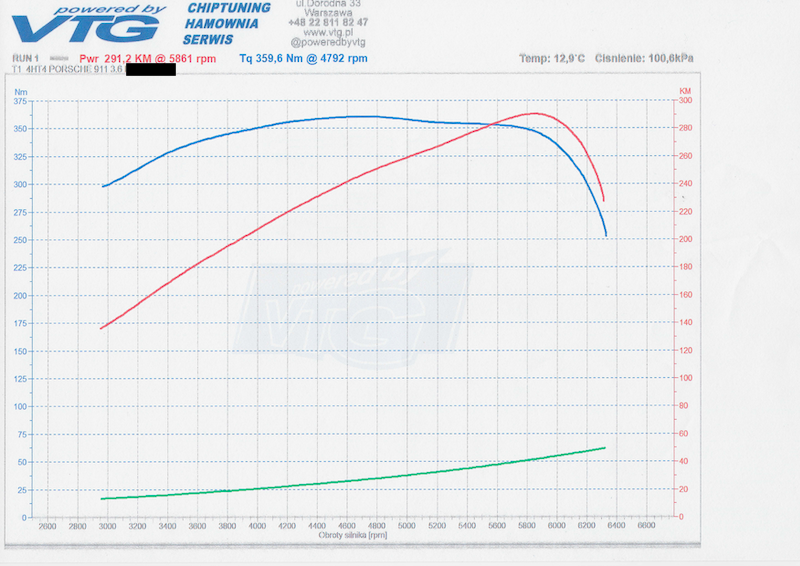

The above engine was built to order with specific requirements to make it as drivable as possible. Instead of a pursuit of raw horse power we focused more on the mid revs and the torque curve. We used a stock 964 engine that was mechanically fully rebuilt using performance components such as, but not limited to, 3.8L Mahle pistons and cylinders, hotter cams, the late 993 VarioRam intake manifold and custom inlet with Piper Cross air filter.

The stock DME controller designed for 964 cannot deal with the upgrades and changes in engine characteristics. Hotter cams, bigger fuel injectors, VarioRam flaps and other engine mods required a new standalone Engine Management System. For this setup we used the Ecumaster EMU.

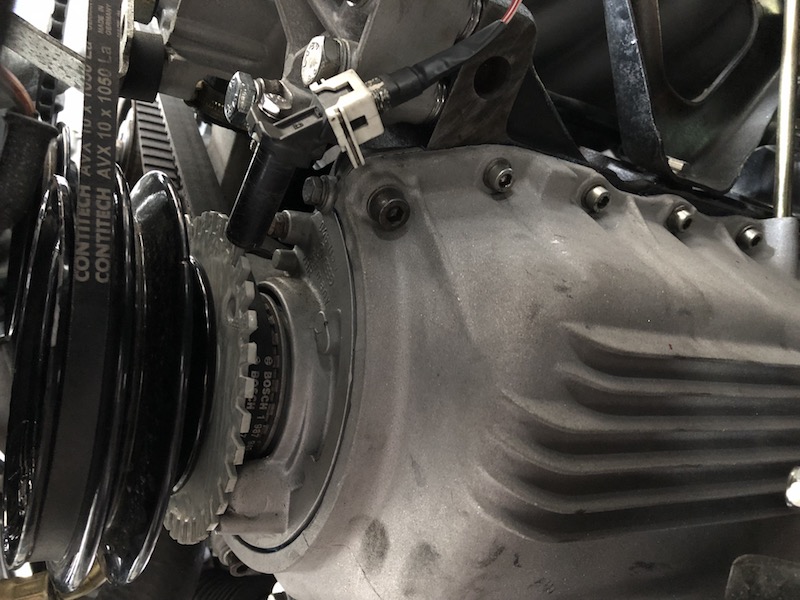

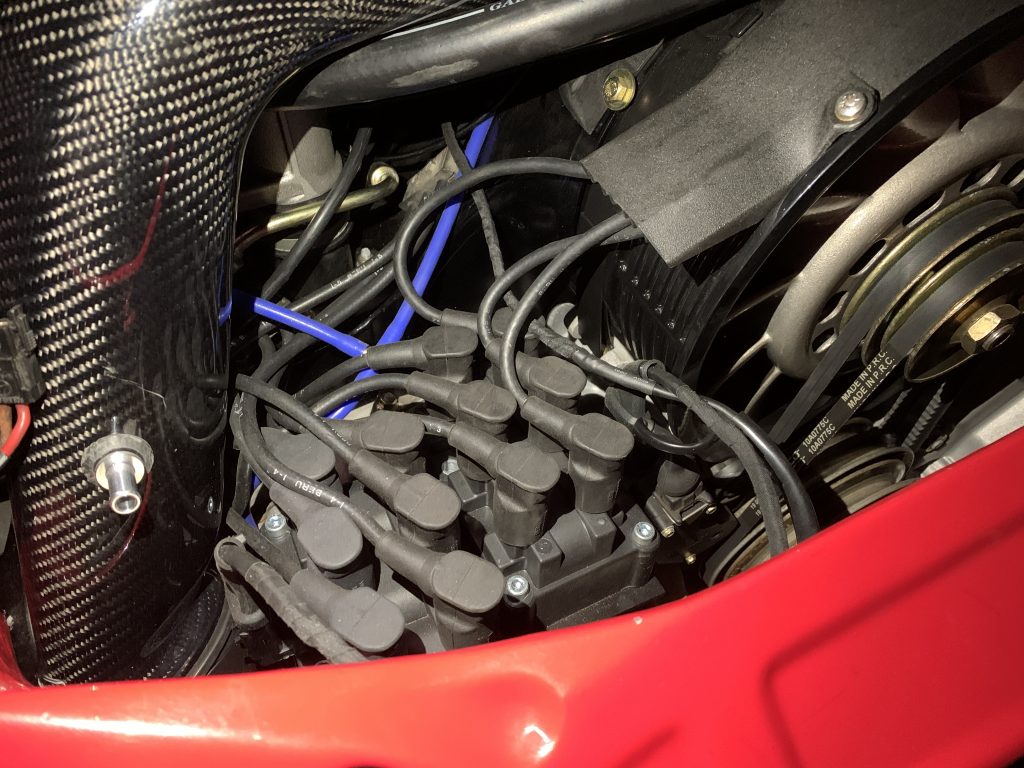

In addition to controlling additional auxiliary components a fully electronic distributor less ignition system was implemented. Ecumaster EMU is directly driving two coil packs configured in Wasted Spark mode. In addition to full control over spark we also removed the mechanical components of distributors that fail over the years.

Just a quick compare of stock values for a standard Porsche 964 and Porsche 993 RS 3.8 reveals how superior is our kit versus stock engine configuration. Not only the max HP and Torque values are better than in the 993 RS 3.8, but these are achieved in much lower RPMs.

Value/Car

Max HP

Max Torque

Stock 964

250PS@6100

310Nm@4800

993 RS 3.8

300PS@6500

355Nm@5400

964 RS 3.8 Kit #1

302PS@6000

374Nm@4500

Porsche 993 – VarioRam and Ecumaster ECU

Similarly to the above 964 engine conversion this one was built to order with specific requirements to make it a fast street car. The early 993 engines did not incorporate the VarioRam intake manifold, and even though the engine delivered more HP than the stock 964 engine, it didn’t give the nice throttle response as it could. Using the VarioRam intake combined with hotter cams and standalone ECU creates a decent torque curve which is much more important in a street car than peak HP. Performance modifications of this engine include VarioRam intake manifold and custom inlet with Piper Cross air filter, hotter cams, standalone ECU, distributorless ignition system, bigger fuel injectors and some additional engine sensors.

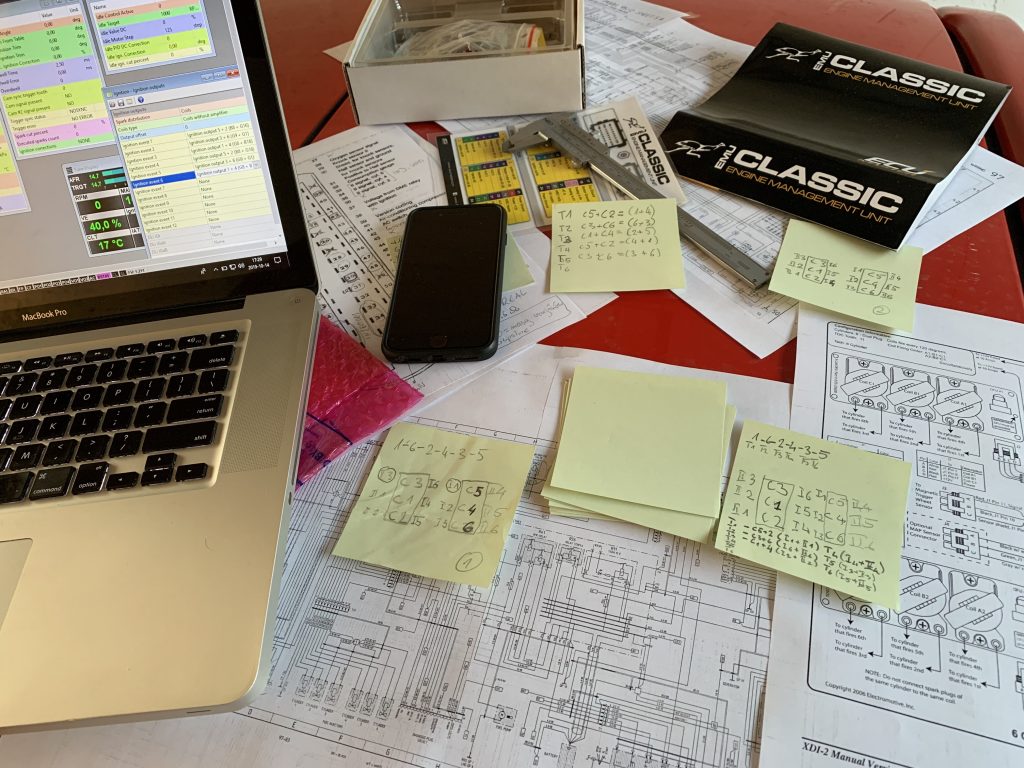

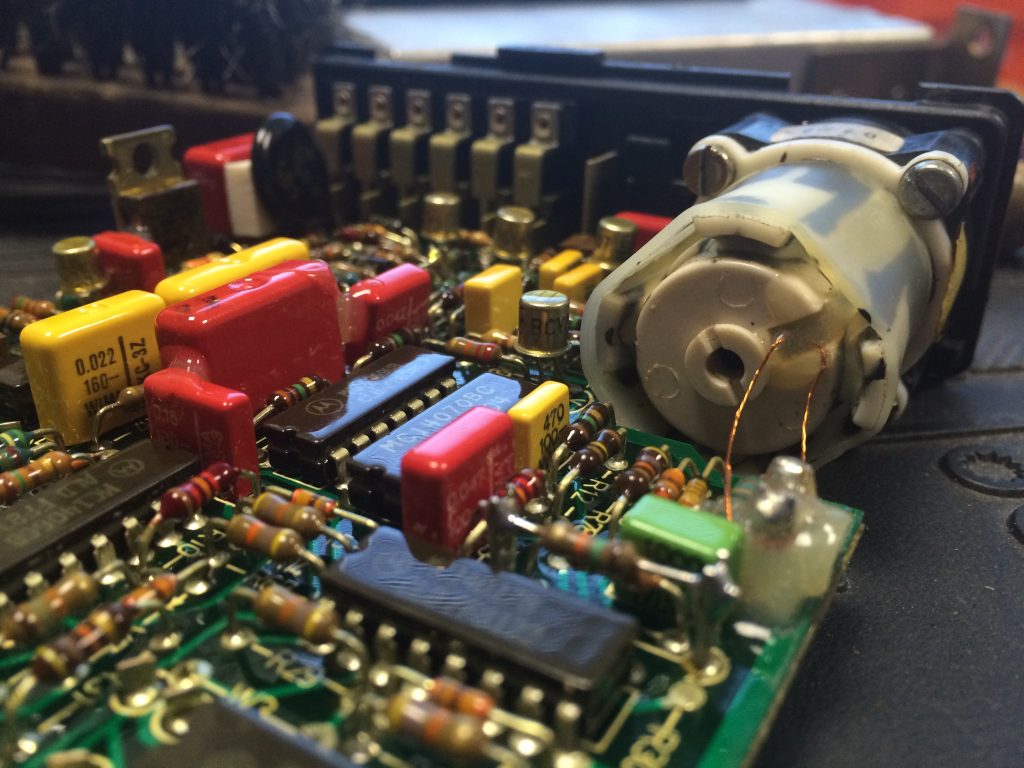

Although it’s possible to use a factory DME of a later 993 model with VarioRam, that one alone is not easy to find. Additional changes to the engine would require chipping the DME, which is also an option. Having a fully adjustable standalone ECU gives the flexibility to fine tune the engine on the dyno and road tune for best individual feel for the driver. Again we chose the Ecumaster EMU Classic standalone ECU – a superb product with a professional support.

Hub dyno is very quiet compared to a rolling road. There is no noise from the tire friction to the rollers. Tuning at the edge of knocking is much easier that way.

Porsche 931 S2 – DITC to MegaSquirt

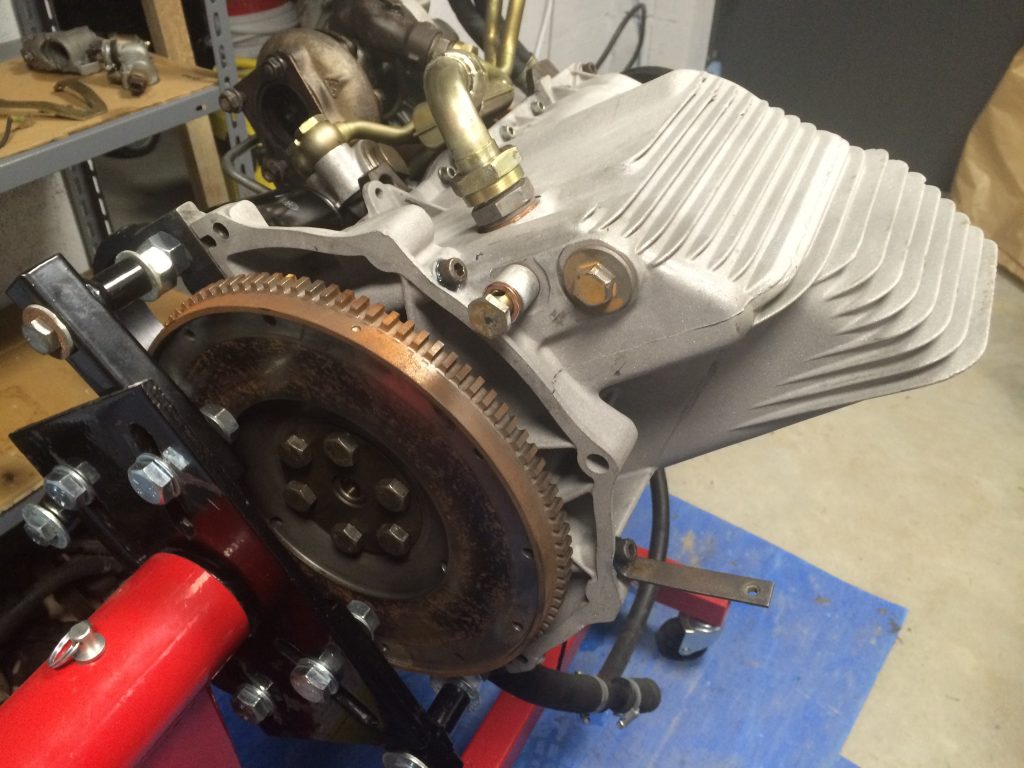

The Porsche 924 Turbo was introduced three years after the famous 930, in 1978. The 924 Turbo (931) utilises well known CIS fuel system and the later ones, not so known Siemens DITC ignition system. The latter one we replaced by us with something from the modern era – MegaSquirt MS2 Standalone ECU.

While one might think of this as an obvious upgrade to factory engine specs, this was not the case here. Engine had few major faults that together led to hydro-lock and bent connection rod. Porsche produced only 13,616 of turbocharged 924s and much less so called S2 equipped with DITC ignition. DITC parts, including the special dual VR flywheel speed sensor are NLA and will brick the car when failed. Used parts will not last in the end. So you’ve got the answer why DITC to MegaSquirt conversion was needed.

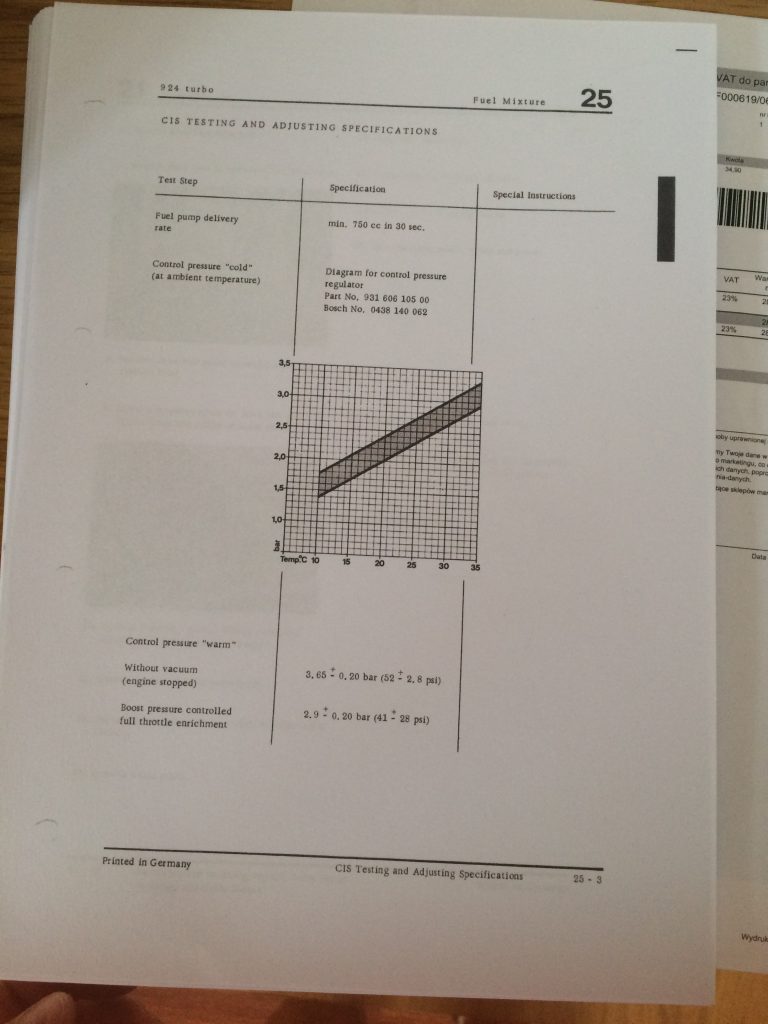

Bosch K-Jetronic is a well known culprit in most older engines not running well or at all scenarios. With that engine, that was just the beginning. Faulty fuel distributor (one line leaking fuel all time) led to engine hydro-lock and bent a connection rod. Engine would not rotate at all. K-Jetronic fuel injection is fuel efficient, gives nice power to the engine, but requires all of it’s components to be in mint condition.

Diagnosing these older engines requires a lot of experience and craftsmanship. You cannot plug in a laptop to read fault codes – there were no OBD systems at that times. One of most important areas for K-Jetronic is fuel pressure. There are three pressures that you play with. System pressure, warm and cold. While system pressure is set once and forget, the warm and cold affect each other. Tricky.

A bent connection rod is a serious warning. But when you don’t see any other damage on the engine internals that should ring a bell. What created such forces that affected only this single element and (almost) nothing else?

The Siemens DITC uses flywheel teeth to calculate accurate position of engine before TDC. A ferromagnetic tooth is added to trigger a signal when full engine revolution passed. This is very high tech in the beginning of the ’80s. Unfortunately almost 40 years later it just fails.

Adding a 36-1 toothed sandwich plate allows to use almost any aftermarket standalone ECU to trigger ignition coils. Going distributor less with a Wasted Sparks setup simplifies the whole thing and does not mechanically wear out.